Micro channel heat exchangers (MCHEs) have become a preferred solution in HVAC systems due to their compact design, energy efficiency, and superior heat transfer performance.

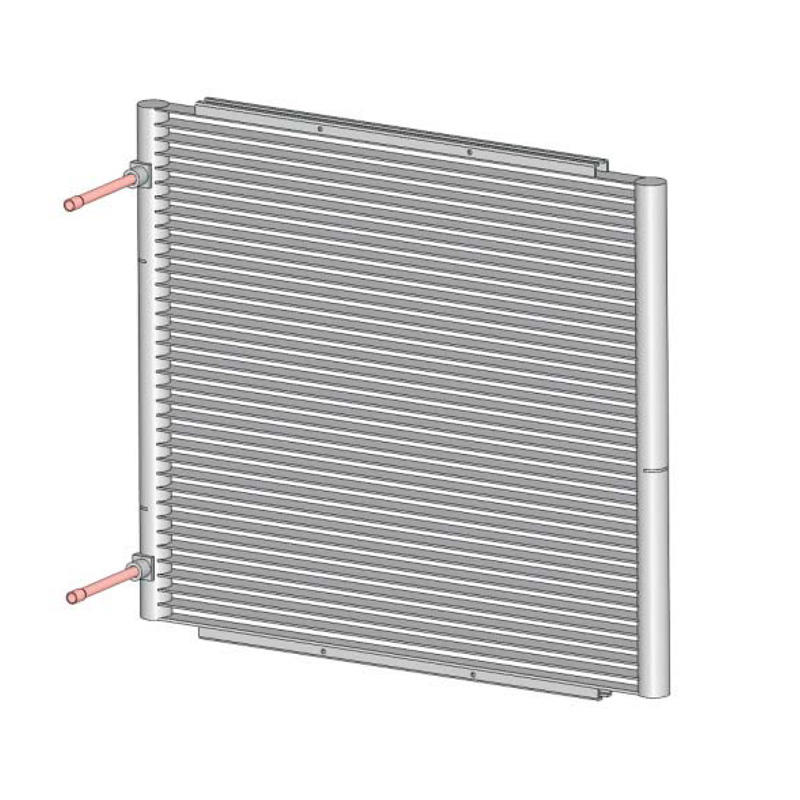

SC-1100 388*346.7mm Car Air Conditioner MCHE Condenser Coil Microchannel Heat Exchanger

Advantages of Micro Channel Heat Exchangers in HVAC Systems

Higher Heat Transfer Efficiency

Micro channel heat exchangers provide up to 30-50% better heat transfer compared to conventional fin-and-tube designs.

The small channels increase surface area contact, improving thermal performance.

Lightweight and Compact Design

MCHEs are up to 50% lighter than traditional copper-and-aluminum heat exchangers.

Their compact size allows for easier installation in space-constrained HVAC units.

Lower Refrigerant Charge Requirements

Micro channel designs require 20-30% less refrigerant, reducing costs and environmental impact.

This makes them compliant with stricter environmental regulations (e.g., EPA, F-Gas).

Improved Corrosion Resistance

Aluminum-based micro channel heat exchangers resist corrosion better than copper tubes, extending lifespan.

Energy Savings

HVAC systems using MCHEs show 5-15% higher energy efficiency due to reduced pressure drop and better airflow.

Micro Channel vs. Traditional Fin-and-Tube Heat Exchangers

| Feature | Micro Channel Heat Exchanger | Traditional Fin-and-Tube |

|---|---|---|

| Heat Transfer Efficiency | 30-50% higher | Standard |

| Weight | Up to 50% lighter | Heavier |

| Refrigerant Usage | 20-30% less | Higher charge required |

| Corrosion Resistance | Better (aluminum design) | Prone to corrosion |

| Installation Flexibility | More compact, easier to fit | Bulkier, harder to install |

Applications in HVAC Systems

Micro channel heat exchangers are widely used in:

Residential & Commercial Air Conditioners – For improved efficiency and space savings.

Heat Pumps – Enhancing performance in both heating and cooling modes.

Refrigeration Units – Reducing refrigerant leaks and maintenance costs.

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>