Micro channel heat exchangers (MCHEs) are becoming the preferred choice for modern HVAC systems due to their superior efficiency, compact design, and long-term cost savings. If you're a wholesale buyer or procurement manager looking for reliable HVAC components, this article explains why MCHEs outperform traditional fin-and-tube heat exchangers and how they can benefit your business.

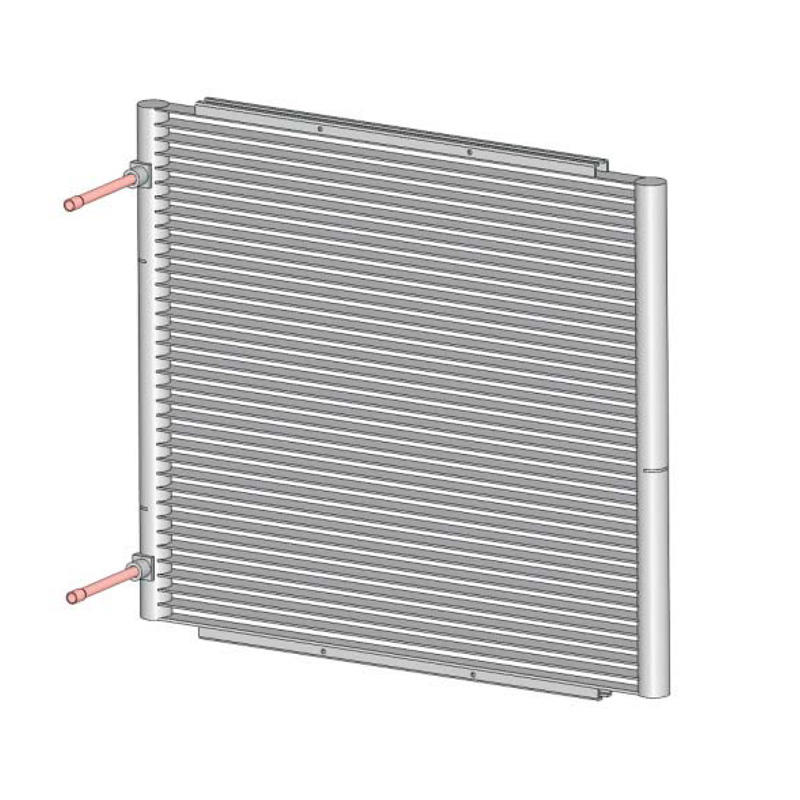

SC-1200 460*431.3mm Microchannel Tube Condenser Coil Heat Exchanger For Cooler

Key Advantages of Micro Channel Heat Exchangers for HVAC

1. Higher Energy Efficiency

MCHEs provide better heat transfer with less refrigerant, reducing energy consumption. Studies show:

20-30% improvement in heat exchange efficiency compared to fin-and-tube designs.

Lower refrigerant charge (up to 40% less), cutting operational costs.

2. Compact and Lightweight Design

50-60% smaller than conventional heat exchangers, saving space in HVAC units.

Aluminum construction makes them 30-40% lighter, reducing shipping and handling costs.

3. Durability and Corrosion Resistance

Aluminum micro channel coils resist salt spray and moisture better than copper-aluminum fins.

Longer lifespan (15+ years) with minimal maintenance.

4. Cost-Effective for Bulk Purchasing

Lower material and refrigerant costs reduce overall system expenses.

Faster installation due to modular designs, saving labor costs.

Micro Channel vs. Fin-and-Tube Heat Exchangers

| Feature | Micro Channel Heat Exchanger | Traditional Fin-and-Tube |

|---|---|---|

| Heat Transfer Efficiency | 20-30% higher | Standard |

| Refrigerant Charge | Up to 40% less | Higher requirement |

| Weight | 30-40% lighter | Heavier |

| Corrosion Resistance | Excellent (aluminum) | Moderate (copper/alu) |

| Installation Time | Faster (modular design) | Slower |

Best Applications for MCHEs in HVAC

Commercial HVAC systems (rooftop units, chillers)

Heat pumps (residential & industrial)

Refrigeration units (supermarkets, cold storage)

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>