In HVAC and refrigeration programs, what are the industry quality practices for mitigating corrosion in Copper Tube Aluminum Fin Heat Exchangers to make sure extended machine reliability and performance?

Mitigating corrosion in Copper Tube Aluminum Fin Heat Exchangers (CTAFHE) is crucial for ensuring extended gadget reliability and performance in HVAC and refrigeration programs. Here are a few enterprise satisfactory practices to address corrosion concerns:

1. **Coating and Surface Treatments:**

- Apply defensive coatings or surface treatments at the aluminum fins to beautify corrosion resistance. These coatings act as a barrier in opposition to corrosive elements inside the air or refrigerants.

2. **Proper Material Selection:**

- Choose fantastic copper and aluminum substances which can be in particular designed for corrosion resistance in HVAC and refrigeration environments. Alloy choice can play a widespread role in lowering susceptibility to corrosion.

3. **Cathodic Protection:**

- Implement cathodic safety techniques, which includes sacrificial anodes or impressed modern-day structures, to limit corrosion by means of promoting the flow of protective currents and preventing the breakdown of materials.

4. **Regular Inspection and Maintenance:**

- Establish a ordinary inspection and upkeep time table to identify and deal with early signs and symptoms of corrosion. Cleaning the warmth exchanger surfaces and doing away with accrued particles can prevent corrosion initiation.

5. **Controlled Environment:**

- Control the surroundings surrounding the heat exchanger to minimize publicity to corrosive factors. This might also involve right ventilation, humidity manipulate, and averting using corrosive cleaning agents.

6. **Water Treatment:**

- If the warmth exchanger is used in programs related to water, put in force water treatment measures to prevent scale formation and corrosion. Regularly screen water great and adjust treatment chemical compounds as wanted.

7. **Corrosion Inhibitors:**

- Introduce corrosion inhibitors into the device to mitigate the corrosive outcomes of refrigerants or different fluids. These inhibitors can help defend the steel surfaces from chemical reactions that cause corrosion.

8. **Avoidance of Dissimilar Metal Contact:**

- Minimize or put off direct contact between dissimilar metals to reduce the risk of galvanic corrosion. Proper insulation or using corrosion-resistant joint materials may be employed to deal with this concern.

9. **Design Considerations:**

- Optimize the layout of the heat exchanger to facilitate proper drainage and save you the pooling of moisture. Poor drainage can lead to localized corrosion and reduce the general system reliability.

10. **Monitoring and Data Logging:**

- Install corrosion monitoring sensors and facts logging structures to music the corrosion price over time. This proactive technique allows for well timed intervention and preservation based on actual-time corrosion statistics.

By enforcing these pleasant practices, HVAC and refrigeration specialists can substantially beautify the corrosion resistance of Copper Tube Aluminum Fin Heat Exchangers, promoting device durability and dependable performance. Regular interest to preservation and environmental elements is fundamental to preventing and mitigating corrosion problems.

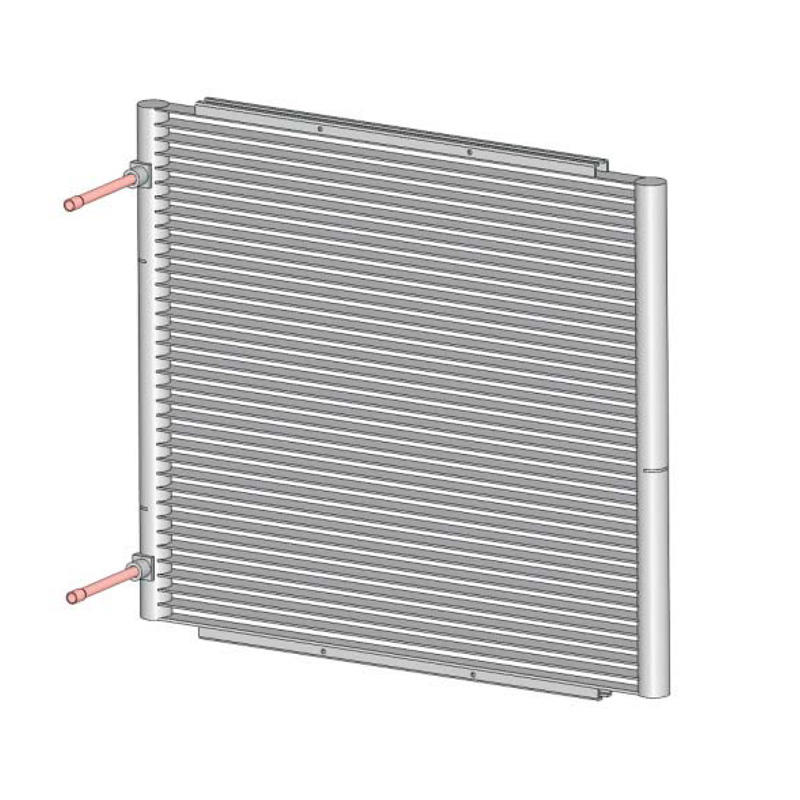

Micro Channel Coil Evaporator With Copper Tube

Micro Channel Coil Evaporator With Copper Tube

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>