In electronics cooling applications, how do MCHE successfully expend heat from electronic components, and what position does their high surface area-to-extent ratio play in optimizing thermal control for digital gadgets?

Micro Channel Heat Exchangers (MCHE) play a crucial position in electronics cooling applications by way of successfully dissipating warmness from digital additives. Here's an explanation of how MCHEs acquire effective warmness dissipation and the function in their high surface place-to-extent ratio in optimizing thermal management for electronic devices:

1. **Enhanced Heat Transfer:**

- The small channels in MCHEs create a large floor place relative to the volume of the warmth exchanger. This extended surface area enables better contact between the coolant or refrigerant flowing thru the channels and the electronic additives that need to dissipate warmness.

2. **Improved Convective Heat Transfer:**

- The high surface place-to-quantity ratio promotes more suitable convective heat transfer. As the coolant or refrigerant flows thru the micro channels, it comes into close touch with the heated surfaces, bearing in mind more efficient warmth switch from the digital additives to the fluid.

3. **Reduced Thermal Resistance:**

- The compact layout of MCHEs minimizes thermal resistance, allowing for more powerful warmness dissipation. This is especially important in electronics cooling, in which reducing the temperature of digital additives is important for retaining most appropriate overall performance and stopping overheating.

4. **Compact and Lightweight Design:**

- The small size and lightweight nature of MCHEs cause them to properly-acceptable for integration into electronic devices with area constraints. Their compact layout permits for efficient heat dissipation with out including good sized bulk or weight to the overall machine.

5. **Precise Temperature Control:**

- The green heat transfer characteristics of MCHEs enable unique temperature control, ensuring that digital components function within their distinctive temperature tiers. This is important for retaining the reliability and sturdiness of electronic devices.

6. **Adaptability to Various Cooling Fluids:**

- MCHEs can be designed to paintings with exclusive forms of cooling fluids, consisting of traditional coolants, refrigerants, or even superior cooling answers. This adaptability permits for personalisation based totally at the unique requirements of the electronic device and the thermal properties of the cooling fluid.

7. **Minimized Flow Maldistribution:**

- The micro channels in MCHEs help reduce glide maldistribution, making sure that the cooling fluid is evenly dispensed throughout the warmth exchanger. This uniform waft distribution contributes to constant and green heat elimination from electronic additives.

In precis, the high floor area-to-volume ratio of Micro Channel Heat Exchangers, blended with their compact layout, helps efficient warmness transfer and dissipation in electronics cooling programs. This capability is essential for retaining the highest quality running temperatures of digital devices, improving their performance, reliability, and overall thermal control.

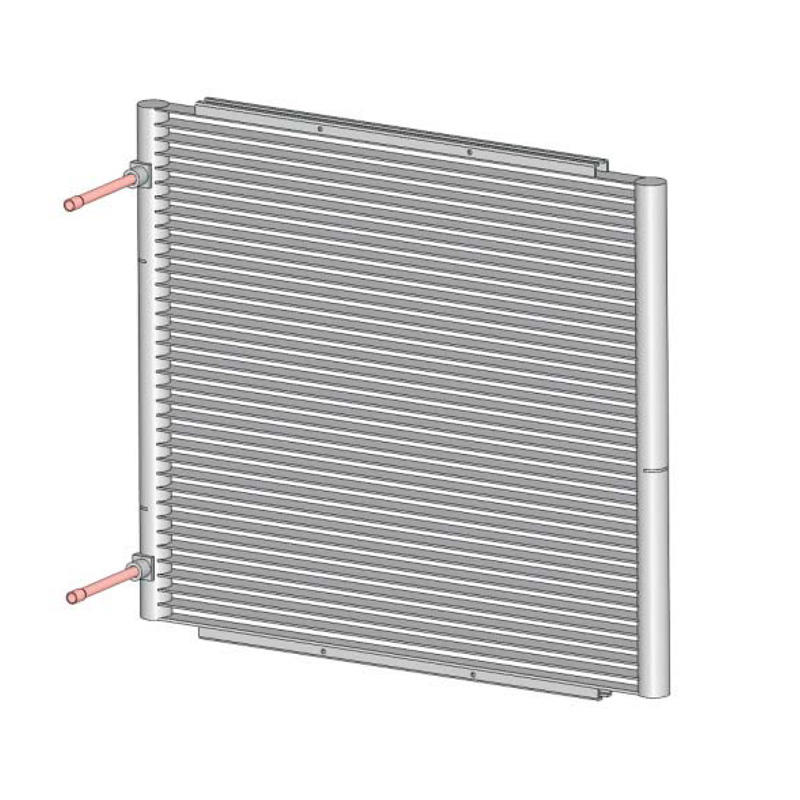

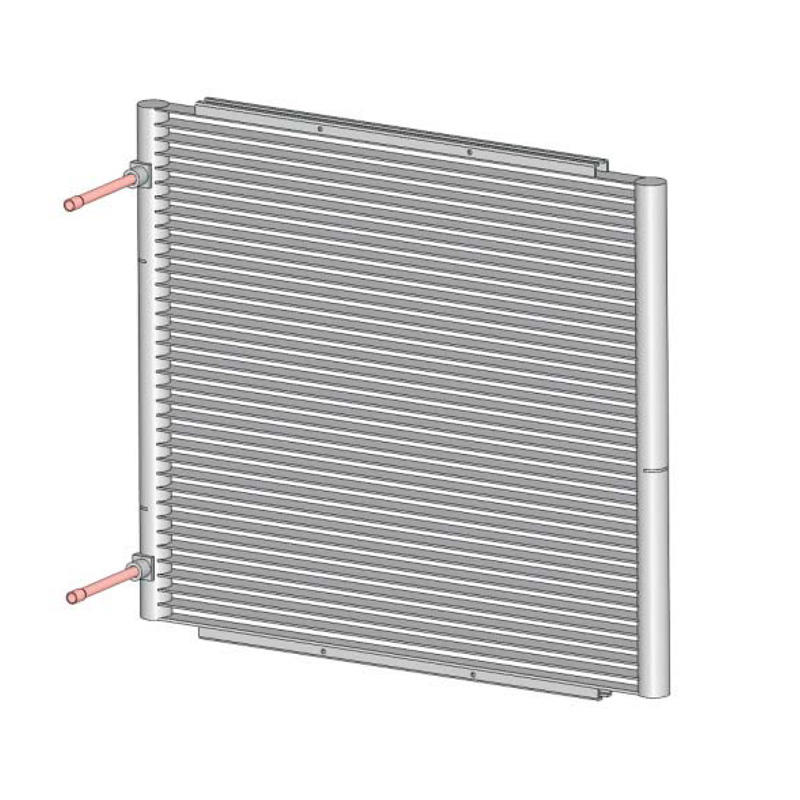

SC-1100 Condenser Coil Micro-Channel Heat Exchanger SC-1100

SC-1100 Condenser Coil Micro-Channel Heat Exchanger SC-1100

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>