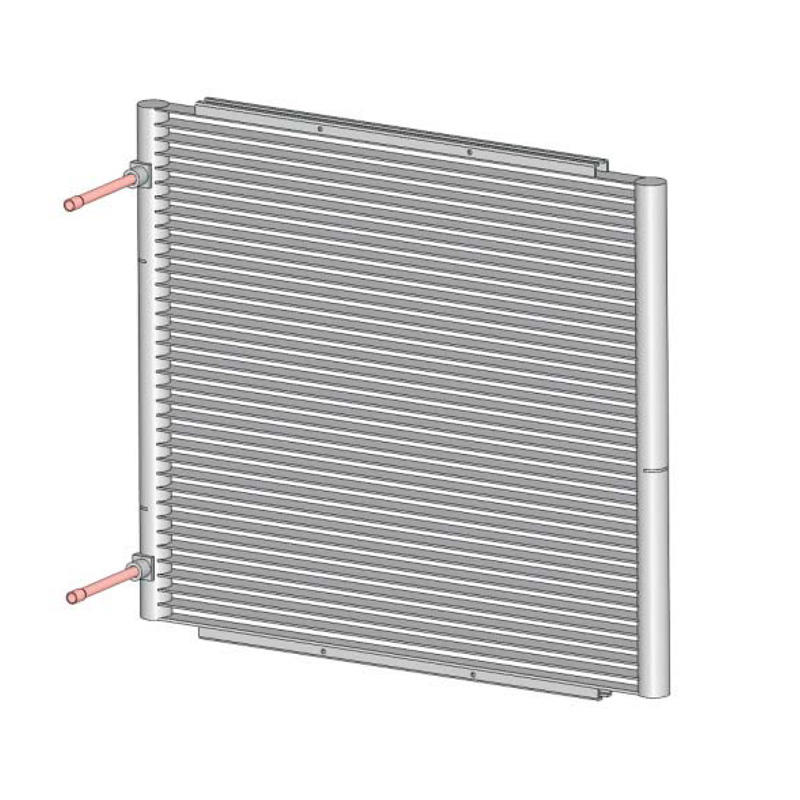

As technology in the heating, ventilation, air conditioning (HVAC) and refrigeration industries continues to develop, choosing the right Condenser Coil (condenser coil) is crucial to improving equipment efficiency and reducing energy consumption. Especially with the increasing awareness of environmental protection and energy saving, enterprises and consumers need to pay more attention to the details of materials, design and performance when choosing condensers. This article will help you choose the most suitable condenser coil according to different needs through an in-depth discussion of **Aluminum Tube Finned Tube Microchannel Condenser Heat Exchanger (MCHE)**.

1. Material advantages: aluminum tube-fin type and micro-channel design

**Aluminum Tube Finned Tube Microchannel Condenser Heat Exchanger (MCHE)** adopts a tube-fin and micro-channel design made of aluminum. Aluminum has the following significant advantages over traditional copper:

Lightweight: Aluminum is lighter than copper and can effectively reduce the overall weight of the equipment. It is especially suitable for household air conditioners and automobile air conditioning systems that require lightweight design.

Corrosion resistance: Aluminum itself has good corrosion resistance. Combined with the micro-channel design, it further reduces the risk of refrigerant leakage and extends the service life of the condenser.

Cost-effectiveness: Compared with copper, aluminum has more advantages in cost, especially in mass production, which can significantly reduce the manufacturing and maintenance costs of condensers.

2. Efficient heat transfer design: Microchannel (Microchannel)

MCHE's microchannel design is an important technological innovation in the refrigeration industry in recent years. Microchannel condensers have high heat transfer efficiency and can complete large heat exchanges in a small volume. This feature is particularly important for many application scenarios.

Efficient energy transmission: The high surface area design of the microchannel improves the heat transfer efficiency between the refrigerant and the air, thereby reducing the energy consumption of the equipment, making it outstanding in energy conservation and environmental protection projects.

Compact design: Because microchannel condensers can achieve equivalent or even higher performance in a smaller space, this gives them unique advantages in space-constrained applications (such as automobiles, household air conditioners, etc.).

3. Application scenarios: household, commercial and industrial refrigeration

When choosing the appropriate Condenser Coil, it needs to be evaluated based on the specific application scenario. Aluminum Tube Finned Tube MCHE is widely used in household, commercial and industrial refrigeration equipment, suitable for the following types of needs:

Domestic and light commercial air conditioning: For domestic and light commercial air conditioning systems, the compact, lightweight and efficient MCHE design is ideal. Its micro-channel design not only reduces the space occupied, but also improves the energy efficiency of the system, meeting the needs of modern families for environmental protection and energy saving.

Large commercial refrigeration and HVAC systems: In large commercial buildings, HVAC systems need to handle huge loads. The efficient heat transfer design of Aluminum Tube Finned Tube MCHE can significantly reduce energy consumption and ensure stable operation of the system under high load. Aluminum's corrosion resistance also reduces maintenance requirements in harsh environments.

Industrial Refrigeration and Cold Chain Transportation: In industrial applications that require continuous and efficient refrigeration, such as cold chain transportation, food processing and storage, choosing a microchannel condenser can ensure that the system operates efficiently in harsh working environments. MCHE's compact design and high efficiency make it ideal for condenser systems in cold chain transportation, enabling faster heat exchange and ensuring that goods are always at the ideal temperature.

4. Industry trends: energy conservation and environmental protection

Currently, the global HVAC and refrigeration industry is facing increasingly stringent environmental regulations and energy efficiency standards, which has promoted technological innovation in energy-saving equipment. Aluminum Tube Finned Tube MCHE has become one of the important products to respond to these trends due to its high efficiency and lightness. Microchannel condensers are increasingly used in new refrigeration systems due to their advantages in energy saving, reducing refrigerant consumption, and adaptability to environmentally friendly refrigerants (such as R32, R410A, etc.).

5. Selection Guide: Customized selection based on needs

In order to choose the right condenser coil, the following points are particularly critical:

Select design based on cooling needs: For home or automotive air conditioning systems with limited space, priority is given to microchannel condensers with compact design and high efficiency. In large-scale commercial or industrial scenarios, an efficient and durable tube-fin design may be more suitable.

Pay attention to material performance: If the equipment needs to operate in a highly corrosive environment, such as a seaside or industrial production area, an aluminum condenser will be a better choice because its corrosion resistance can effectively extend the life of the equipment.

Energy efficiency is a priority: Against the backdrop of rising energy prices and increasingly stringent environmental regulations, condensers with efficient heat transfer designs and low energy consumption are preferred. Aluminum Tube Finned Tube MCHE excels in this area and can help reduce long-term operating costs.

Aluminum Tube Finned Tube Microchannel Condenser Heat Exchanger (MCHE) combines the lightweight, corrosion-resistant properties of aluminum with the efficient heat transfer capabilities of microchannel design, and is a popular condenser coil product on the market. Whether in the field of household air conditioning, small commercial equipment or industrial refrigeration, MCHE is able to provide customized solutions according to different needs.

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>