Comparison between MCHE and traditional heat exchangers: performance, cost and application scenario analysis

1. Performance comparison

Heat exchange efficiency:

MCHE: Due to its microchannel design, MCHE can provide higher heat exchange efficiency and reduce pressure loss of fluid flow.

Traditional heat exchanger: The heat exchange efficiency is relatively low, especially in the application scenario of high temperature difference.

Volume and weight:

MCHE: Small size and light weight, suitable for applications with limited space.

Traditional heat exchanger: Usually large size and heavy weight, not suitable for compact design.

Corrosion resistance:

MCHE: Specific materials can be used to enhance corrosion resistance and extend service life.

Traditional heat exchanger: prone to corrosion in certain environments, high maintenance cost.

2. Cost comparison

Initial investment:

MCHE: The manufacturing process is complex and the initial investment is high, but it can save energy costs in the long run.

Traditional heat exchanger: The initial investment is relatively low, but the operation and maintenance costs are high.

Maintenance cost:

MCHE: Less maintenance requirements, reducing long-term use costs.

Traditional heat exchangers: require regular maintenance and cleaning, which increases the overall cost.

3. Application scenario analysis

Applicable fields:

MCHE: widely used in automotive air conditioning, refrigeration equipment, electronic equipment heat dissipation and other fields with high space and efficiency requirements.

Traditional heat exchangers: commonly used in large industrial systems, heating and cooling systems and other occasions with low volume and weight requirements.

Environmental adaptability:

MCHE: highly adaptable and can maintain efficient operation under various working conditions.

Traditional heat exchangers: performance may decline in extreme environments, affecting efficiency.

Although MCHE may have a higher initial investment, its excellent performance, low maintenance costs and ability to adapt to a variety of application scenarios make it increasingly popular in many industries. For applications that require efficient and compact design, MCHE is undoubtedly a more attractive choice.

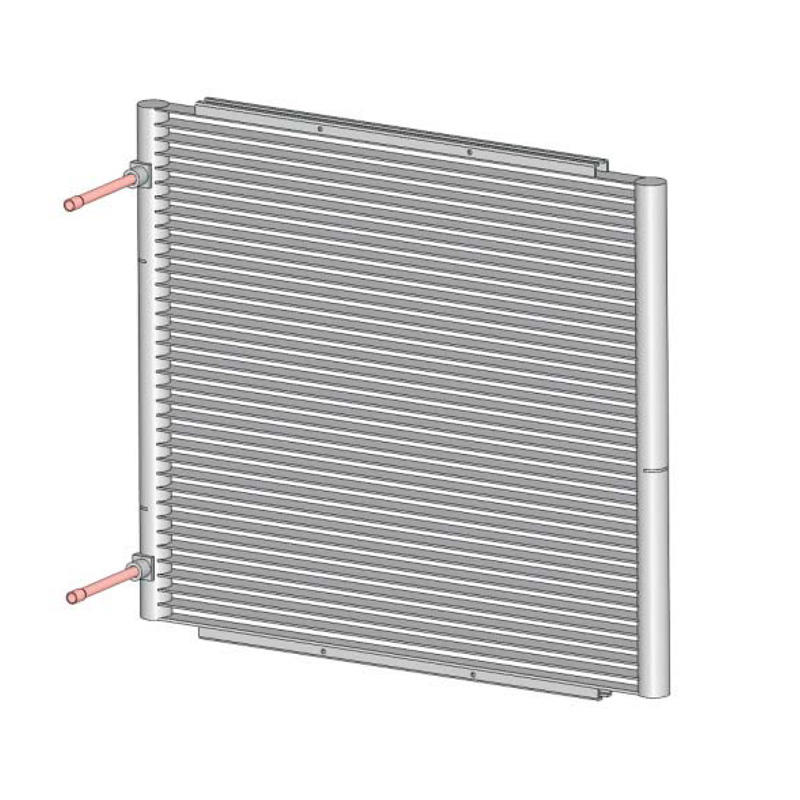

SC-1000 333.2*299.7mm Micro-Channel Heat Exchanger Condenser Coil For Refrigerator

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>