For the electric vehicle industry, the heat dissipation performance of the battery pack is directly related to the safety and service life of the battery. What is the application effect of Aluminum Tube Aluminum Fin Heat Exchanger in electric vehicle battery cooling system? Can its thermal conductivity effectively reduce battery temperature and improve battery pack performance?

In the electric vehicle industry, the heat dissipation performance of the battery pack is a key factor in ensuring battery safety, stability and service life. The application effect of Aluminum Tube Aluminum Fin Heat Exchanger (aluminum tube aluminum fin heat exchanger) in the electric vehicle battery cooling system is remarkable, and its thermal conductivity can effectively reduce the battery temperature and improve the performance of the battery pack.

Here are several reasons to support the effectiveness of Aluminum Tube Aluminum Fin Heat Exchanger in electric vehicle battery cooling systems:

Efficient thermal conductivity: Aluminum is a material with good thermal conductivity. The aluminum tube and aluminum fin heat exchanger uses the thermal conductivity of aluminum to quickly transfer the heat generated by the battery from the battery pack to the heat exchanger. This helps reduce heat build-up inside the battery and lowers battery temperature.

Excellent heat dissipation performance: As the main part of heat dissipation, aluminum fins have a large surface area, which can effectively increase the contact area with air, thereby improving heat dissipation efficiency. Through the fan on the radiator or natural convection, the heat on the aluminum fins can be quickly dissipated to the surrounding environment, further reducing the battery temperature.

Compact structural design: The internal space of electric vehicles is limited, so the battery cooling system needs to have a compact structural design. Aluminum tube and aluminum fin heat exchangers generally have a compact size and can be easily installed in or around the battery pack without taking up too much space.

Excellent corrosion resistance: Electric vehicle battery cooling systems need to operate in complex environments for a long time, including high temperature, high humidity, chemical corrosion, etc. Aluminum tube and aluminum fin heat exchangers have good corrosion resistance and can operate stably for a long time in these harsh environments.

Customizability: Electric vehicle battery packs vary in shape, size and cooling needs, and aluminum tube and aluminum fin heat exchangers can be custom designed to meet specific needs. This helps ensure that the cooling system fully adapts to the characteristics of the battery pack for optimal cooling.

By lowering the battery temperature, the aluminum tube and aluminum fin heat exchanger can effectively improve the performance of the battery pack. High temperatures will have a negative impact on the battery's chemical reactions, reducing the battery's energy density, cycle life and safety performance. Lowering the battery temperature can slow down these negative effects and improve the battery's energy utilization, cycle times and safety performance.

The application effect of Aluminum Tube Aluminum Fin Heat Exchanger in the electric vehicle battery cooling system is remarkable. Its thermal conductivity can effectively reduce the battery temperature and improve the performance of the battery pack.

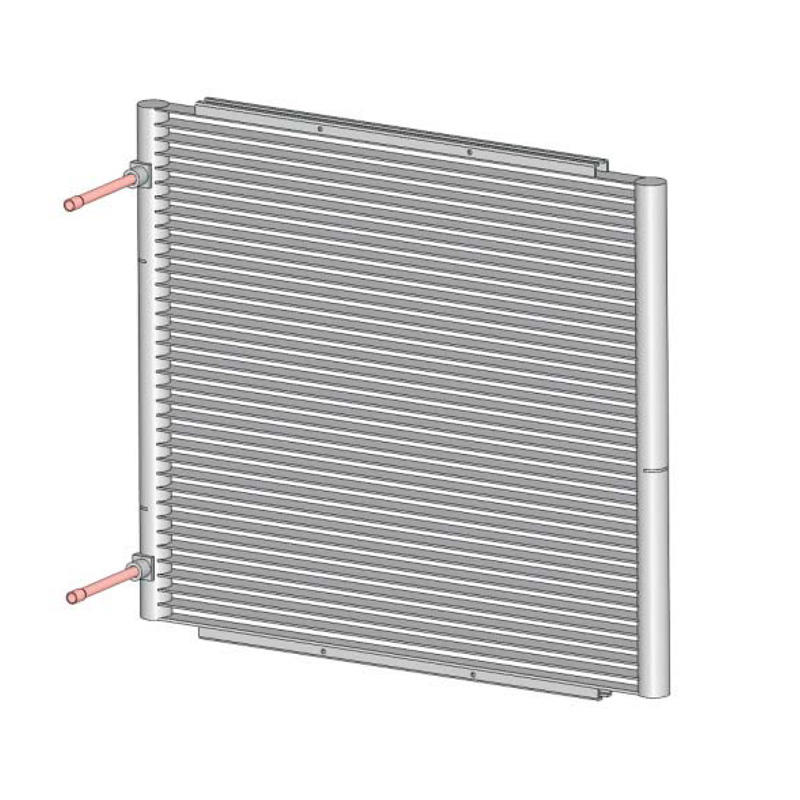

Aluminum Tube Finned Tube Microchannel Condenser Heat Exchanger MCHE

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>