In the aerospace field, there are extremely high requirements on the weight and structural strength of equipment. Can the lightweight characteristics of Aluminum Tube Aluminum Fin Heat Exchanger be able to meet the weight restrictions of radiators for aerospace equipment while ensuring its structural strength and heat dissipation performance?

In the aerospace industry, equipment weight and structural strength are extremely important considerations during the design and manufacturing process. For Aluminum Tube Aluminum Fin Heat Exchanger (aluminum tube aluminum fin heat exchanger), its lightness can indeed meet the weight restrictions of aerospace equipment on radiators to a large extent, and its structural strength and heat dissipation performance can also be guaranteed. .

First of all, aluminum is a lightweight metal with low density and light weight. Therefore, using aluminum as the main material of the radiator can significantly reduce the overall weight of the radiator, which is very beneficial for aerospace equipment. At the same time, aluminum also has good thermal conductivity and can quickly and effectively transfer heat from the heat source to the heat sink to ensure the heat dissipation effect.

Secondly, the structural design of aluminum tube and aluminum fin heat exchangers is usually carefully calculated and optimized to ensure sufficient structural strength while meeting heat dissipation performance. The structure and arrangement of the fins, pipe diameter, wall thickness and other parameters will be designed and adjusted according to specific application scenarios to ensure that the radiator can still maintain a stable working condition under complex environmental conditions such as pressure and vibration.

In addition, the aerospace field has very strict requirements on the material selection, manufacturing process and testing standards of radiators. Aluminum tube and aluminum fin heat exchangers need to follow high-standard quality control processes during the manufacturing process to ensure that each radiator meets the design requirements and has good reliability and durability. At the same time, strict performance testing and environmental adaptability testing are required before leaving the factory to ensure that it can work stably and reliably in aerospace equipment.

The lightweight nature of Aluminum Tube Aluminum Fin Heat Exchanger can meet the weight restrictions of radiators for aerospace equipment, while its structural strength and heat dissipation performance can also be guaranteed. Through reasonable material selection, structural design and manufacturing technology, it can be ensured that aluminum tube and aluminum fin heat exchangers are widely used in the aerospace field.

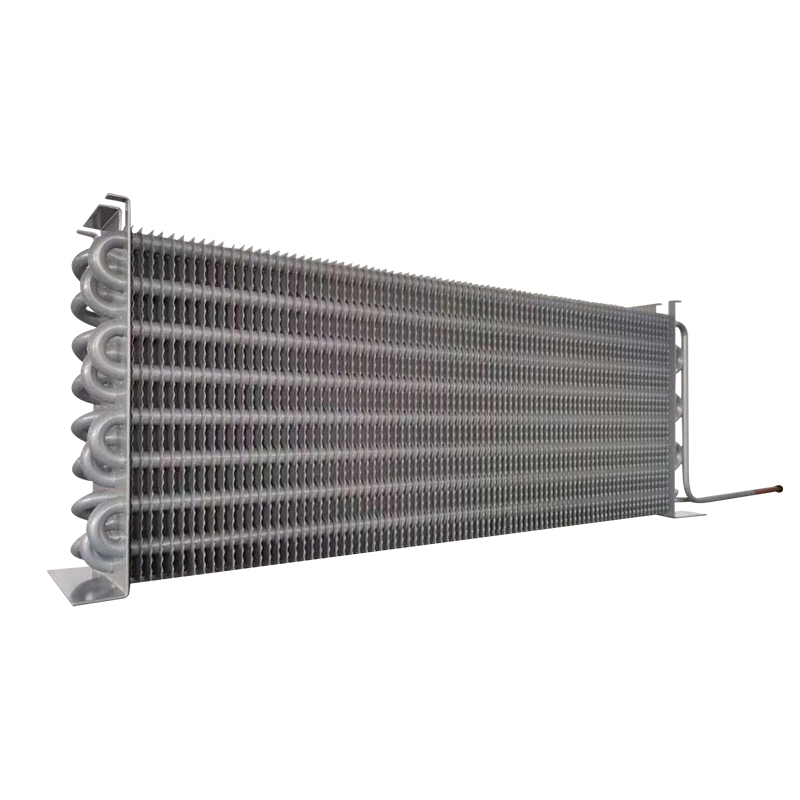

Aluminum Tube Finned Tube Microchannel Condenser Heat Exchanger MCHE

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>