In the field of marine engineering, high-salt, high-humidity, and highly-corrosive environments place extremely high performance requirements on heat exchangers. Can Micro Channel Heat Exchanger meet the long-term stable operation requirements in such harsh environments?

For the field of marine engineering, the high-salt, high-humidity, and highly corrosive environment indeed places extremely high requirements on the performance of heat exchangers. The long-term stable operation of the Micro Channel Heat Exchanger in such a harsh environment requires comprehensive consideration of factors such as material selection, structural design, and anti-corrosion measures.

First of all, material selection is the key to ensuring that the Micro Channel Heat Exchanger operates stably in the marine environment. Using materials with excellent corrosion resistance, such as stainless steel, titanium alloys or some special alloys, can effectively resist the erosion of salt and corrosive substances in seawater. In addition, surface treatment techniques such as coating or passivation can further enhance corrosion resistance.

Secondly, structural design is also crucial to the performance of the heat exchanger. The microchannel heat exchanger increases the heat transfer area by reducing the size of the flow channel, thereby improving the heat transfer efficiency. However, in marine environments, this compact structure may also increase the risk of corrosion. Therefore, anti-corrosion measures need to be fully considered in the design, such as optimizing the flow channel structure to reduce the retention of corrosive substances, and using well-sealed connections to prevent seawater penetration.

Finally, anti-corrosion measures are also an important means to ensure the stable operation of Micro Channel Heat Exchanger in the marine environment. In addition to selecting corrosion-resistant materials and optimizing structural design, regular maintenance, cleaning and component replacement can also be used to reduce the impact of corrosion. In addition, for corrosion problems under specific environmental conditions, special anti-corrosion coatings or additives can also be developed to enhance the corrosion resistance of the heat exchanger.

Although the application of Micro Channel Heat Exchanger in the field of marine engineering faces environmental challenges of high salt, high humidity, and high corrosiveness, through reasonable material selection, structural design, and anti-corrosion measures, it is possible to meet the long-term stable operation in this harsh environment. need. However, the specific application effects still need to be verified and evaluated through actual engineering cases and long-term operating data.

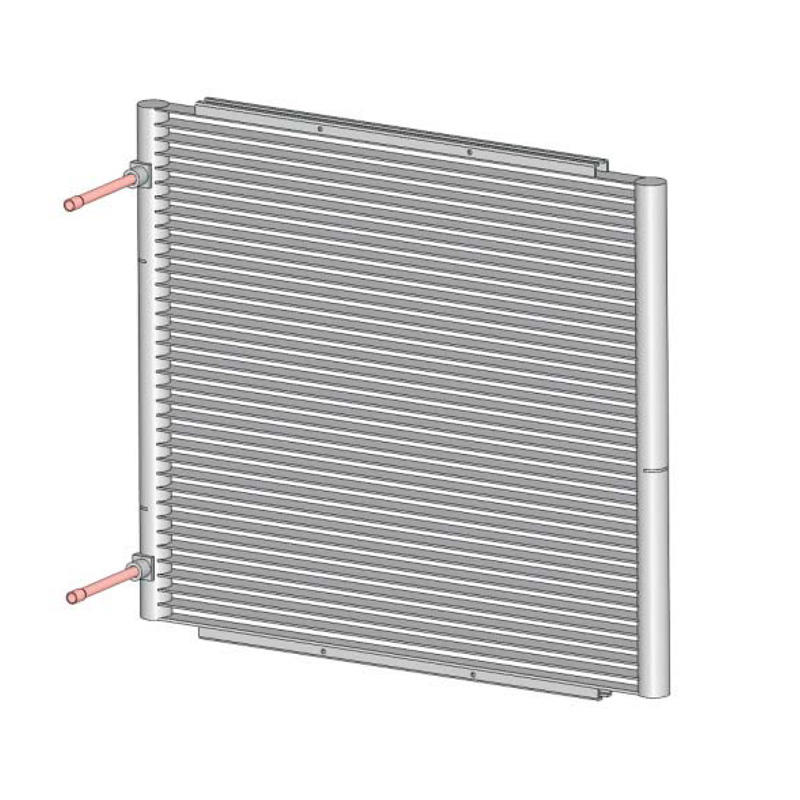

SC-1000 333.2*299.7mm Micro-Channel Heat Exchanger Condenser Coil For Refrigerator

SC-1000 333.2*299.7mm Micro-Channel Heat Exchanger Condenser Coil For Refrigerator

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>