A heat exchanger is a device used for heat transfer, and its main function is to transfer heat from one fluid to another. Usually the two fluids do not come into direct contact, but the heat is transferred through the wall of the heat exchanger. Heat exchangers are widely used in industries such as industry, construction, chemical industry, energy, etc., such as air conditioning, HVAC systems, automobile engines, cooling systems, etc.

Working principle of heat exchanger:

Separation of two fluids: The heat exchanger is designed so that heat transfer occurs between two fluids, and these two fluids usually flow through different pipes or channels to avoid direct contact. Heat is transferred from one fluid to another through the wall or metal film of the heat exchanger.

Heat transfer: During the flow process, the heat of one fluid is transferred to the wall, and the heat on the wall is transferred to the other fluid. In this way, the higher temperature fluid transfers heat to the lower temperature fluid, causing the temperature of the two fluids to change.

Heat exchange process: Depending on the type of heat exchanger, the heat exchange process can be different flow modes such as parallel flow, countercurrent flow or cross flow.

Parallel flow: The two fluids flow in the same direction, and the heat transfer is less.

Countercurrent: Two fluids flow in opposite directions, with the strongest heat exchange effect and the highest heat transfer efficiency.

Crossflow: The fluid flows in a vertical or cross manner, which is suitable for some special occasions.

Types of heat exchangers:

Shell and tube heat exchanger: This is the most common type, generally consisting of a set of tubes and a shell. One fluid flows through the tube and the other flows in the shell. Shell and tube heat exchangers are commonly used in petrochemical, air conditioning and refrigeration industries.

Plate heat exchanger: It is composed of multiple metal plates, and multiple fluid channels are formed between the plates. The fluid flows along the surface of the plate for heat exchange. Plate heat exchangers have high heat transfer efficiency and are widely used in chemical engineering, food processing and other fields.

Air-cooled heat exchanger: Use air as a cooling medium to take heat away from the hot fluid. Commonly used in automobile radiators, cooling towers, etc.

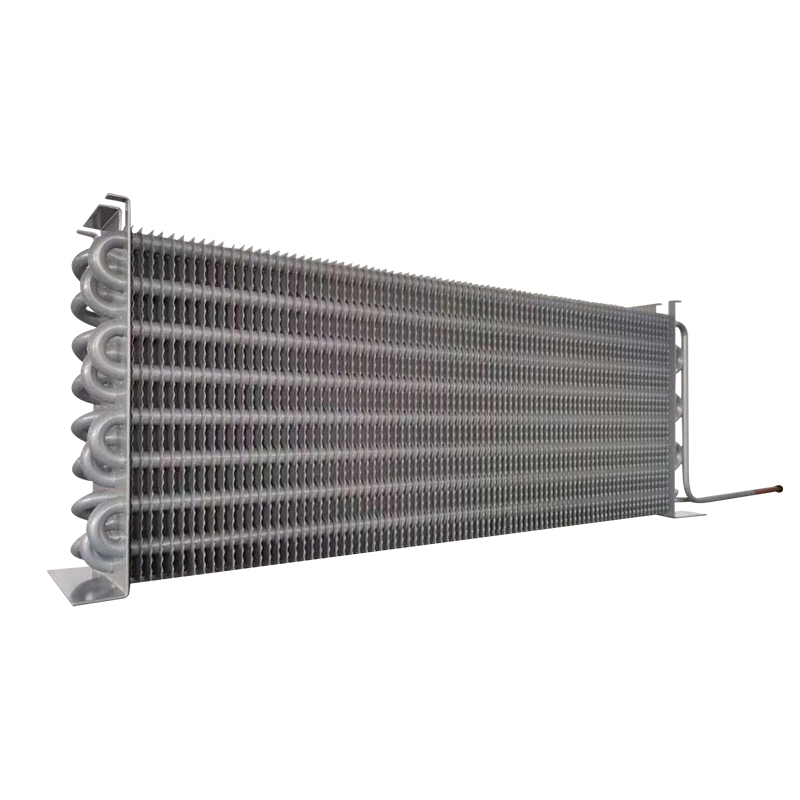

Fin heat exchanger: Increase the heat exchange surface area by adding fins to improve the heat exchange efficiency. Commonly used in small equipment such as air conditioners, automobile cooling systems, etc.

Applications of heat exchangers:

Industrial cooling: Many industrial processes generate a lot of heat that needs to be cooled by heat exchangers.

Air conditioning and HVAC: Heat exchangers are used in cooling and heating systems to transfer heat from air conditioners, water heaters or other equipment.

Energy recovery: Heat exchangers are used in many energy systems to recover and utilize waste heat.

Automotive cooling systems: Used to cool vehicle engines to ensure that the engine remains at the appropriate operating temperature.

SC-1000 333.2*299.7mm Micro-Channel Heat Exchanger Condenser Coil For Refrigerator

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>