Microchannel condenser is a heat exchange device widely used in refrigeration and air-conditioning systems. Its compact structure and efficient heat exchange capacity give it significant advantages in improving system efficiency. However, the complexity of microchannel structures requires balancing multiple parameters during the optimization design process, especially the relationship between heat transfer and pressure drop.

Working principle and heat transfer characteristics of microchannel condenser

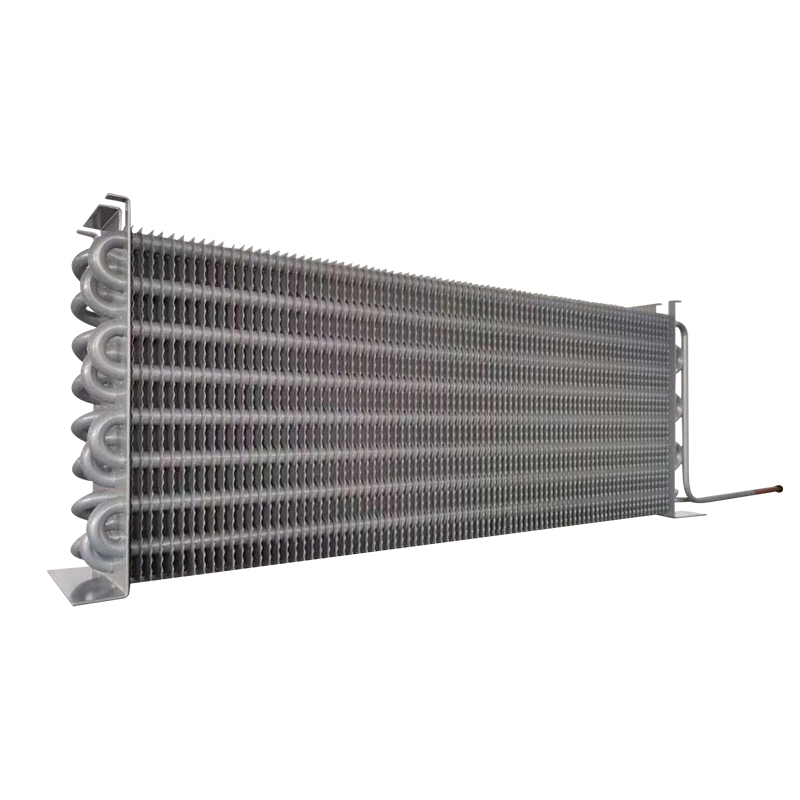

The core working principle of the microchannel condenser is based on the efficient heat exchange mechanism of fluid passing through multiple tiny channels. The high inner wall area and fine flow structure of the microchannel help increase the area for heat exchange, thereby improving thermal efficiency. This paper analyzes the heat transfer process of aluminum finned tube microchannel condenser and discusses the effects of fin shape, spacing and tube structure on the heat transfer coefficient.

Pressure drop problem and influencing factors

Pressure drop is a key challenge in microchannel condenser design. Higher pressure drops result in increased energy consumption and affect the overall performance of the system. Through theoretical analysis and numerical simulation, this paper studies the influence of different design parameters (such as pipe diameter, fin height and spacing, etc.) on pressure drop, and proposes an optimization scheme to reduce pressure drop.

Optimization design method

In order to balance the heat transfer efficiency and pressure drop, this paper proposes an optimization design method based on fluid mechanics and thermodynamic models. This method adjusts the key parameters of the microchannel condenser through a multi-objective optimization algorithm, aiming to optimize both the heat transfer efficiency and the pressure drop performance. The experimental results show that appropriate tube structure design and fin configuration can significantly improve the thermal efficiency of the condenser while effectively reducing the pressure drop.

Experiment and result analysis

This paper combines numerical simulation with experimental data to verify the optimized design of aluminum tube fin tube microchannel condenser. Experimental results show that the optimized design improves thermal efficiency by about 15% and reduces pressure drop by 20% compared with traditional condensers. These results indicate that the optimization method proposed in this paper has great potential in practical applications.

Aluminum Tube Finned Tube Microchannel Condenser Heat Exchanger MCHE

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>