Researchers have responded to the rise in power densities of electronic devices by exploring new technologies that can keep devices cool without compromising performance. Microchannel heat exchangers use small channels containing diameters less than a millimeter to transfer heat between liquids - this allows it to be much smaller than conventional plate-and-frame heat exchangers and make for an effective cooling solution in compact electronics, as well as becoming increasingly popular within automotive industries.

Microchannel heat exchangers are heat sinks equipped with narrow channels that enable fluids to pass easily between them, facilitating heat transfer quickly and effectively. Furthermore, their small size provides high surface area-to-volume ratios that provide highly efficient cooling systems while simultaneously decreasing overall system size.

Microchannel heat exchangers offer many advantages when it comes to cooling small portable devices like smartphones and tablets. Their design enables manufacturers to utilize thinner walls and smaller fans, further reducing weight and size while improving cooling. As a result, microchannel heat exchangers have become the go-to technology for mobile electronic cooling systems.

Though microchannel heat exchangers offer many advantages, some challenges must first be resolved for microchannel heat exchangers to become the go-to technology for cooling. Clogging, which occurs because of their small sizes and greater particle exposure than traditional heat exchangers, must be prevented by using high-quality coolants with lower viscosities to decrease fouling risks.

As mentioned previously, microchannel heat exchangers must be designed specifically for the operating conditions in which they will be used to achieve maximum performance. They should be capable of adapting to different air velocities while avoiding condensation and corrosion - this can be accomplished using special long-life aluminum alloys in their construction and brazing techniques to form strong metallic bonds at their joints.

Microchannel heat exchangers can help bring down the costs associated with refrigeration equipment by eliminating certain components from its design. For instance, direct expansion systems no longer need an expensive refrigerant distributor, while microchannel heat exchangers allow for reduced refrigerant charges and smaller fans - two additional benefits of using them.

As such, the microchannel heat exchanger market is set for steady expansion over time. Unfortunately, a recession could alter this growth path; industries could reduce capital spending and production operations which in turn impacts demand for microchannel heat exchangers which are known for their compact designs and enhanced efficiencies. Still, energy-saving technologies will remain essential to driving market expansion; using innovative heat exchangers will reduce carbon emissions and further drive market expansion as the economy improves; eventually, microchannel heat exchangers may become even more sought-after as commercial and residential applications than before.

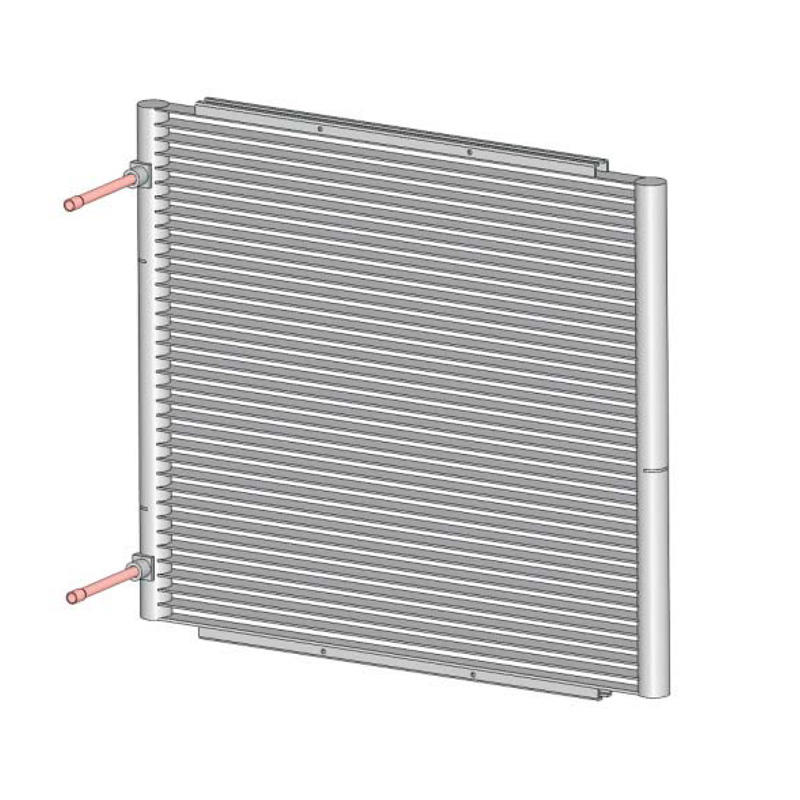

SC-1100 388*346.7mm Car Air Conditioner MCHE Condenser Coil Microchannel Heat Exchanger

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>