Working principle

The core of the Microchannel Tube Condenser Coil Heat Exchanger lies in its microchannel structure. This structure greatly increases the contact area between the fluid and the wall by forming tiny channels on the tube wall, thereby improving the heat exchange efficiency. When the refrigerant or cooling medium flows through these microchannels, it can quickly remove heat and dissipate the heat to the environment through the condenser.

Application areas

Refrigeration and air conditioning field

In refrigeration and air-conditioning systems, MCHE is used as a condenser, which can significantly improve the energy efficiency ratio (EER) and cooling capacity of the system. Its compact structural design not only reduces the size of the equipment, but also reduces the weight, making it easier to install and maintain. At the same time, MCHE's high thermal conductivity allows the refrigerant to complete the heat exchange process at lower pressure and temperature, thereby reducing energy consumption.

Electronic cooling

As the integration level and power density of electronic devices continue to increase, heat dissipation issues have become increasingly prominent. MCHE has been widely used in the field of electronic cooling due to its efficient heat dissipation capabilities. By integrating MCHE near the main heat source of electronic equipment, heat can be quickly exported and dissipated into the air to ensure stable operation of electronic equipment. Especially in areas where high-density electronic equipment is concentrated, such as data centers and server rooms, the application of MCHE is particularly important.

Industrial cooling

In industrial cooling systems, such as cooling towers, cooling water circulation systems, etc., MCHE also shows its unique advantages. Its efficient and compact structural design enables industrial cooling systems to operate more efficiently, reducing energy consumption and operating costs.

advantage analysis

High heat exchange efficiency

The microchannel structure of MCHE greatly increases the contact area between the fluid and the wall, making the heat exchange process more efficient. At the same time, the fluid flow rate in the microchannel is faster, further improving the heat exchange efficiency.

Compact structure

Compared with traditional heat exchangers, MCHE has a more compact structure, and its volume and weight have been significantly reduced. This not only saves installation space, but also reduces transportation and installation costs.

Energy saving and environmental protection

MCHE's efficient heat exchange performance enables the system to complete the heat exchange process with lower energy consumption, thereby reducing operating costs. At the same time, its compact structural design also reduces the use of materials, which is in line with the development trend of energy conservation and environmental protection.

High reliability

MCHE is made of high-quality materials, such as aluminum alloy, which has high corrosion resistance and fatigue resistance. At the same time, its reasonable structural design and sophisticated workmanship enable MCHE to maintain stable performance in harsh working environments.

Future trends

With the continuous advancement of science and technology and the continuous expansion of application fields, MCHE will show the following development trends in the future:

Technological innovation: With the continuous development of material science and manufacturing technology, MCHE's manufacturing process will continue to be optimized and innovated to further improve its heat exchange performance and reliability.

Multi-field applications: MCHE will not only be limited to refrigeration and air conditioning, electronic cooling and industrial cooling, but will also gradually expand to automotive thermal management, aerospace and other fields.

Intelligent development: With the widespread application of technologies such as the Internet of Things and big data, MCHE will gradually realize intelligent control and management, improving the automation level and operating efficiency of the system.

Environmental protection and energy saving: MCHE will continue to develop in the direction of environmental protection and energy saving, using more environmentally friendly materials and manufacturing processes to reduce energy consumption and emissions.

Microchannel Tube Condenser Coil Heat Exchanger, as an efficient and compact heat exchange technology, has shown great application potential and advantages in the fields of refrigeration and air conditioning, electronic cooling and industrial cooling.

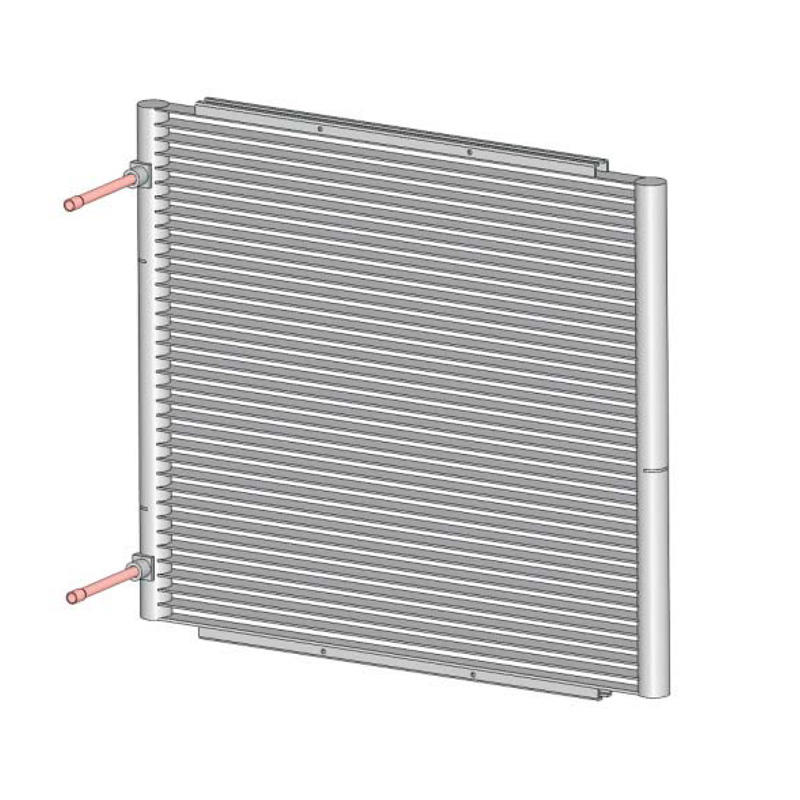

SC-1200 460*431.3mm Microchannel Tube Condenser Coil Heat Exchanger For Cooler

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>