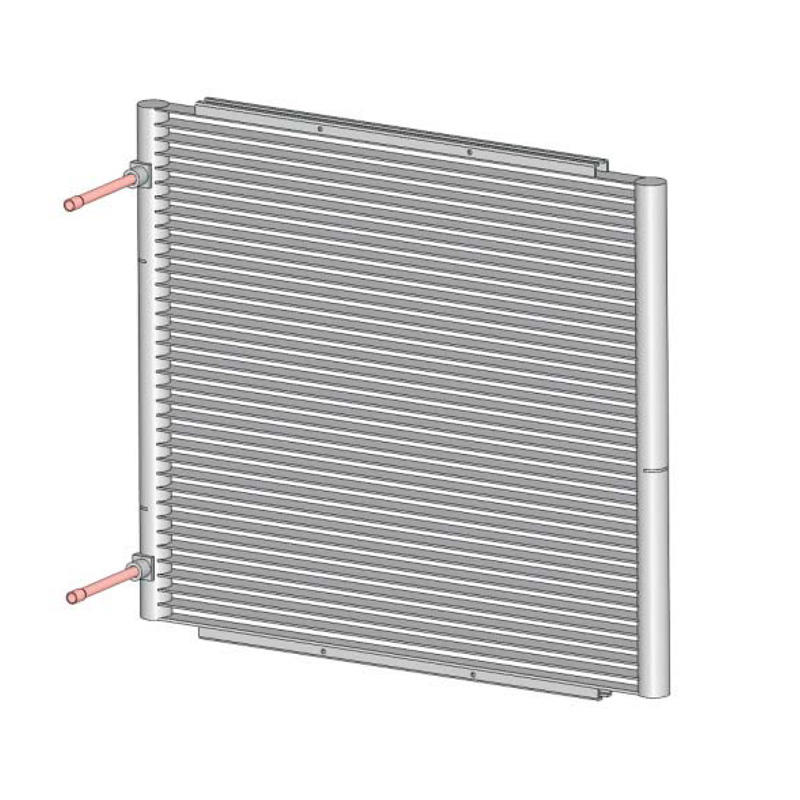

Understand the basic parameters of MCHE

When choosing an MCHE model, you need to understand the following key parameters:

Size: The size of the MCHE directly affects its heat dissipation capacity and adaptability. Choose the right size according to the space requirements to ensure that the device can operate effectively in the target environment.

Material: Commonly used materials include aluminum, copper, etc., and factors such as environmental corrosiveness, heat conduction efficiency, and cost need to be considered when choosing. Aluminum is often used in most applications because it is light and has good thermal conductivity.

Number and shape of channels: The number and shape of microchannels affect the efficiency of heat exchange. More and smaller channels usually mean higher efficiency, but may also increase manufacturing costs.

Heat exchange area: The heat exchange area determines the efficiency of heat exchange. Under the same space constraints, a larger heat exchange area can provide better heat exchange performance.

Working pressure: Choose the right MCHE model according to the system's working pressure to ensure that the heat exchanger can withstand the required working pressure without leakage or damage.

Considerations for the application environment

Operating temperature range: Different MCHE models have different operating temperature ranges. When selecting, make sure that they can adapt to the operating environment temperature of the system. For example, in high-temperature environments, specially designed MCHEs may be required.

Humidity and corrosive environments: When working in humid and highly corrosive environments, it is important to choose MCHE models with corrosion resistance. Consider coatings or specific alloy materials to increase durability.

System power requirements: If the application scenario has high heat dissipation requirements, such as high-performance air conditioning or industrial cooling systems, choosing MCHE models with higher heat exchange efficiency can optimize energy efficiency.

Choosing the right fluid type

Different MCHE models are suitable for different types of fluids, such as air, water, refrigerants, etc. When selecting, make sure that the MCHE is compatible with the fluid used in the system.

For example, air conditioning systems usually use refrigerants as the working medium, and you need to choose an MCHE type that can optimize refrigerant flow and heat exchange.

Performance index comparison

Heat exchange efficiency: When choosing, the heat exchange efficiency of the MCHE should be considered. You can refer to the technical manual or the supplier's performance data to choose a model with the required thermal efficiency.

Flow and pressure loss: The flow and pressure loss of an MCHE will affect its efficiency. Excessive pressure loss will increase the cost of system operation, so choosing a model with low pressure loss can help improve overall energy efficiency.

Noise level: In some applications, noise is an important consideration. Make sure the MCHE model you choose can operate efficiently with minimal noise.

Cost and budget considerations

Initial cost: Choose an MCHE model in the right price range based on your budget. Efficient MCHE models may require a higher initial investment, but they can bring higher energy efficiency and lower maintenance costs in the long run.

Long-term costs: Consider the long-term costs of MCHE maintenance, energy consumption, and service life. MCHEs with good energy efficiency will bring a higher return on investment.

Cost-effectiveness: Balance performance and cost to choose the model that best suits the application needs and fits your budget.

Maintainability and reliability

Cleaning and maintenance: The ease of cleaning of the MCHE should also be considered. Choose a model that is easy to clean and has low maintenance costs, especially in high-pollution, high-load working environments.

Failure rate and reliability: Understand the failure rate and reliability of different MCHE models. You can select the most stable model by checking user feedback or comparing products.

Environmental protection and compliance

Environmental protection standards: Ensure that the selected MCHE model complies with relevant environmental protection regulations, such as low energy consumption and low emissions.

Compliance certification: Select a certified MCHE model to ensure that its performance meets industry standards and safety requirements.

How to choose the right MCHE model

Summarize how to comprehensively consider factors such as MCHE size, materials, performance indicators, application environment and budget to select the most suitable model.

Emphasize the need for communication with suppliers during the selection process and regular evaluation and upgrade of equipment.

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>