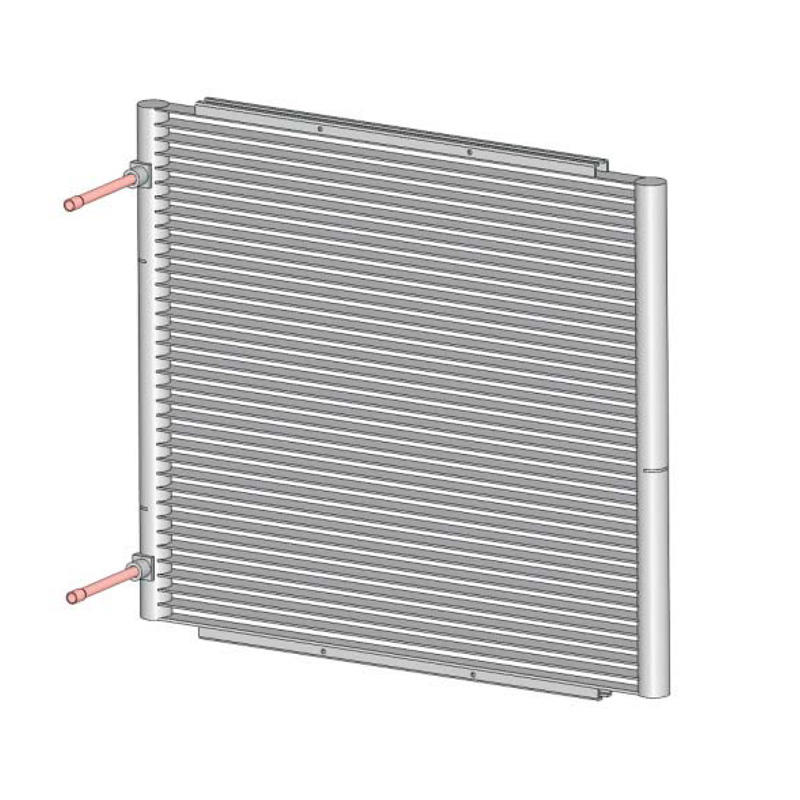

Structure and principle of G-shaped elbow fin condenser:

The core feature of the G-shaped elbow fin evaporator condenser is that its pipe adopts a G-shaped bending design, which greatly increases the contact area of the airflow and optimizes the heat exchange effect. Compared with the traditional straight pipe condenser, the G-shaped elbow fin design can provide more efficient heat exchange in a smaller space. This combination of pipes and fins not only improves the refrigeration efficiency, but also effectively reduces the volume of the equipment, making the air conditioning system more compact.

Pipeline design: The G-shaped elbow design can better guide the flow of the coolant, so that it can exchange heat with the cooling air more evenly. This design can effectively improve the efficiency of heat exchange and reduce the heat loss of the refrigerant during the flow process.

Fin structure: The design of the fins not only enhances the heat exchange, but also provides more flow paths for the airflow, so that the contact time between the air and the condenser surface is prolonged, further improving the heat exchange effect.

Energy saving benefits: Due to the improvement of heat exchange efficiency, the energy consumption of air conditioning equipment has been effectively reduced. This is undoubtedly a huge advantage for modern industrial and household air-conditioning equipment that pursues energy saving and environmental protection.

Application fields of G-shaped elbow fin condenser:

Air conditioning industry: As one of the key components of the air conditioning system, the G-shaped elbow fin evaporator condenser can greatly improve the refrigeration performance of the air conditioner. With the increase in demand for air conditioning, especially in high temperature environments, high-efficiency and small-volume heat exchangers have become a technical problem that the air conditioning industry urgently needs to solve.

Industrial air conditioning cooling: Industrial air conditioning usually requires higher refrigeration capacity and stronger stability. The application of G-shaped elbow fin evaporator condenser in industrial air-conditioning equipment not only improves the refrigeration efficiency, but also can withstand greater working pressure and high temperature environment, ensuring the temperature control requirements in the industrial production process.

Refrigerator and freezing equipment: In some refrigeration equipment in low temperature environments, G-shaped elbow fin condenser is also widely used due to its structural advantages. This design not only improves the heat exchange efficiency, but also reduces energy consumption and adapts to low temperature working conditions.

Advantages:

Efficient heat exchange: The G-shaped elbow fin design significantly improves the cooling efficiency, shortens the heat exchange time, and thus improves the cooling effect.

Energy saving and environmental protection: Efficient heat exchange reduces the energy consumption of air conditioning and industrial air conditioning systems, which is in line with the increasing global attention to energy saving and environmental protection.

Compact design: Compared with traditional designs, the G-shaped elbow fin condenser has a more compact structure, occupies less space, and is suitable for the needs of modern miniaturized equipment.

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>