In the chemical industry, corrosion of heat exchangers caused by corrosive substances produced by chemical reactions is indeed a long-standing challenge. The presence of corrosive substances will not only cause damage to the heat exchanger, but may also affect the stability and safety of the entire production process. Therefore, finding a heat exchanger with strong corrosion resistance is crucial for the chemical industry.

Micro Channel Heat Exchanger (Micro Channel Heat Exchanger) exhibits excellent corrosion resistance due to its unique design and material selection. This heat exchanger uses a tiny channel structure to increase the flow rate of the fluid in the channel, thus improving the heat transfer efficiency. At the same time, its materials are usually made of special alloys or composite materials with excellent corrosion resistance. These materials can effectively resist the erosion of corrosive substances.

Specifically, the strong corrosion resistance of Micro Channel Heat Exchanger is mainly reflected in the following aspects:

Material selection: Use special alloys or composite materials with excellent corrosion resistance, which can withstand the erosion of corrosive substances for a long time without being damaged.

Structural design: The microchannel design makes the fluid more evenly distributed within the heat exchanger, reducing the possibility of local corrosion. At the same time, the compact structure also reduces the contact area with corrosive substances, further reducing the risk of corrosion.

Surface treatment: By using advanced surface treatment technologies, such as coating or passivation, the corrosion resistance of the heat exchanger can be enhanced and its service life extended.

Therefore, Micro Channel Heat Exchanger has broad application prospects in the chemical industry. It not only provides a reliable and long-lasting solution to the chemical industry, but also improves the stability and safety of the production process. Of course, in practical applications, it is also necessary to select appropriate materials and designs based on specific process conditions and the nature of corrosive substances to ensure the best performance and long-term stable operation of the heat exchanger.

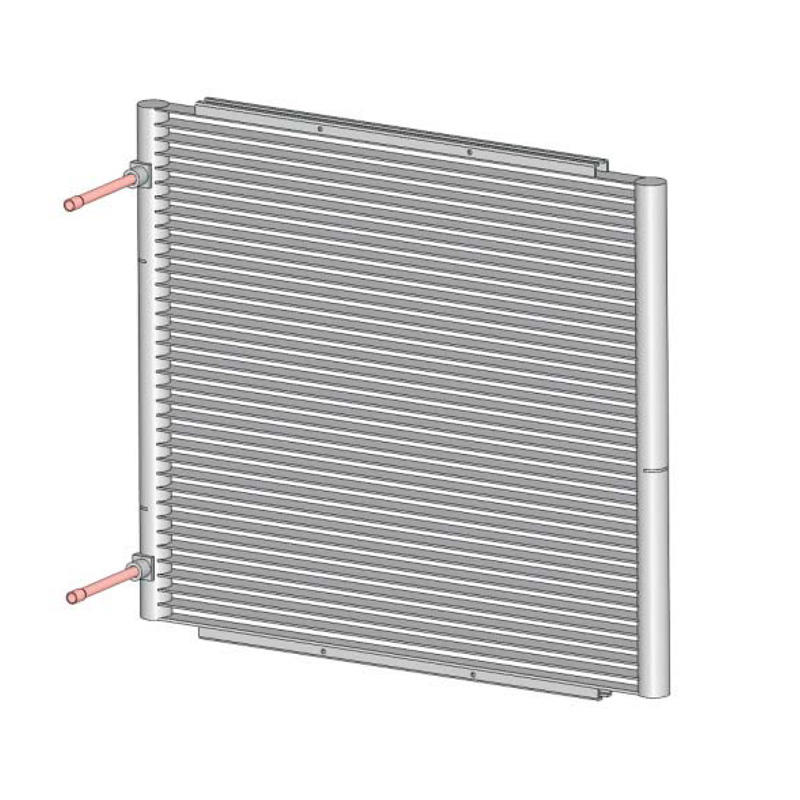

SC-1400 780*769.7mm Microchannel Tube Heat Exchanger Condenser Coil For Freezer

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>