The core component of microchannel tube heat exchangers is microchannel tubes, which are usually made of aluminum alloy materials and the size of the tubes is generally 1~3 mm wide. Due to its efficient thermal conductivity, microchannel tubes can greatly improve the heat exchange efficiency, especially in miniaturized condensers and evaporators.

During the heat exchange process, the fluid circulates through the microchannel pipes, and the surrounding air or cooling medium exchanges heat through the pipe surface. Thanks to the smaller size of the microchannel, the flow velocity of the fluid is higher, which increases the contact area of the heat exchange, thereby effectively improving the efficiency of the heat exchange.

Application in evaporators

In evaporators, microchannel tubes are mainly used to absorb heat from the refrigerant. Due to the efficient thermal conductivity of microchannel tubes, it can achieve higher heat exchange effects in a smaller volume, thereby greatly improving the overall performance of the evaporator. Microchannel evaporators are usually smaller and lighter than traditional tube evaporators, and can provide higher refrigeration efficiency.

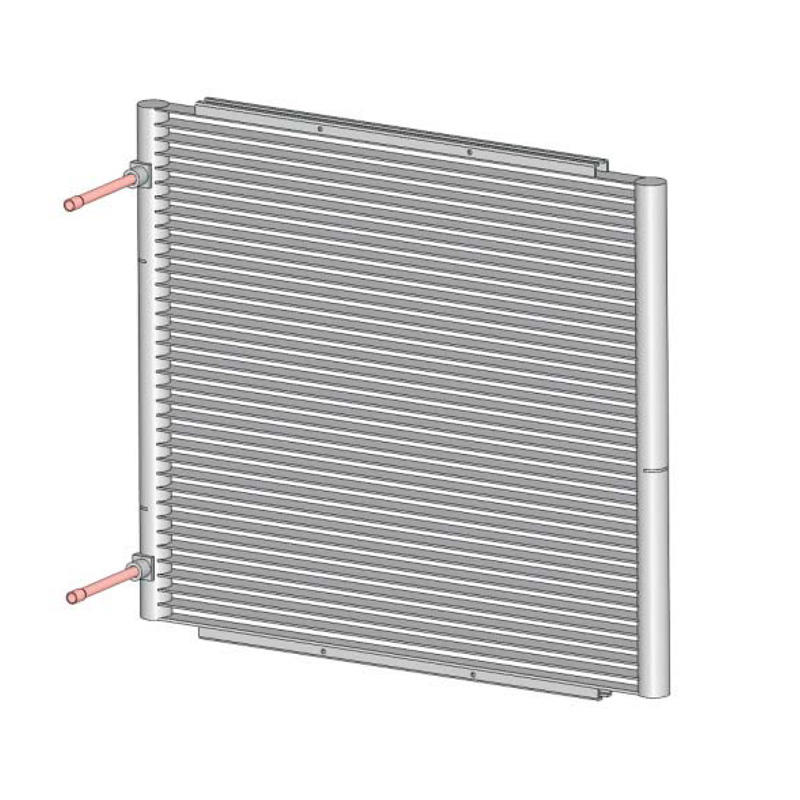

Application in condenser

In the condenser, the microchannel tube is responsible for transferring the heat of the refrigerant to the external cooling medium (such as air or water). Due to the larger surface area of the microchannel tube, the heat exchange efficiency can be effectively improved, thereby shortening the time of the condensation process and improving the overall operating efficiency of the system. In addition, the microchannel tube condenser is smaller and lighter than the traditional tube condenser, which is easy to install and maintain.

Dimensions and Design

Take 1274*1358mm as an example. This size of microchannel tube heat exchanger is usually used in medium to large refrigeration systems. The specific size design usually depends on the cooling requirements of the system, the temperature range of condensation or evaporation, and the spatial layout. Factors such as fluid flow, heat exchange efficiency, pressure loss, and manufacturing cost should be considered during the design.

Advantages and Challenges

The advantages of microchannel tube heat exchangers include:

High efficiency: The microchannel design makes the heat transfer effect of the heat exchanger more significant, and more heat exchange can be completed in a shorter time.

Compactness: Due to its compact design, the microchannel tube heat exchanger occupies less space, which is very suitable for modern space-limited equipment.

Lightweight: Compared with traditional copper tube heat exchangers, microchannel tubes are lightweight and easy to install.

Cost-effective: Microchannel tubes made of aluminum alloy have lower costs and high production efficiency compared to copper tubes.

SC-1900 1274*1358mm Microchannel Tube Evaporator Heat Exchanger Condenser Coil

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>