1. Applications on ships and ships

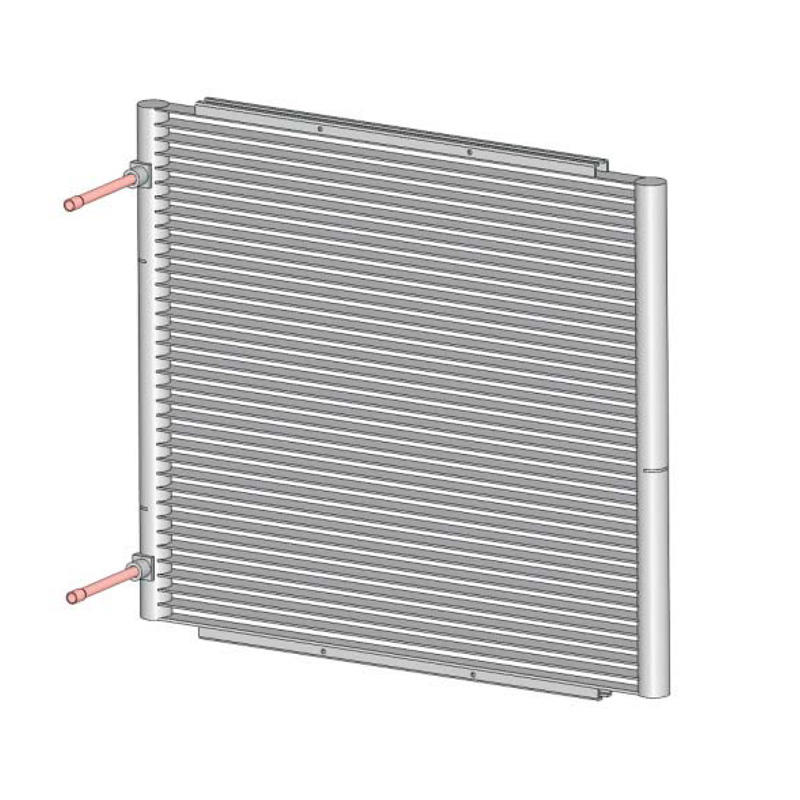

When the ship is sailing, it is absolutely not allowed to have quality problems in the heat exchanger due to military tasks. Heat exchangers are important components in ships and ships. The quality of heat exchangers affects the power of ships and ships, resulting in ships and ships unable to sail. Double cooling tube double tube sheet heat exchangers are also widely used in ships and ships.

2. Application in petrochemical industry

Application of double cooling tube double tube sheet heat exchanger in petrochemical industry In 2004, it was equipped with Shandong Hualu Hengsheng 48000m3/h air separation unit supercharger final stage heat exchanger, and the heat medium was 200℃, 7.0MPa dry Air and cold medium are industrial water, and the dry air of the heat medium is cooled by the final heat exchanger and then enters the air separation unit for low temperature and high pressure separation at -200°C, so the cooling water is absolutely not allowed to enter the cold box. Once the cooling water enters the cold box , Under low temperature conditions, the cooling water rapidly freezes and expands in volume, resulting in inestimable losses. The use of double cooling tubes and double tube sheet heat exchangers can ensure the safety of the equipment.

3. Application in the power industry

The heat exchangers of the stator and rotor of large motors are usually heat exchangers with a single cooling tube and a single tube sheet structure, but in special occasions, such as nuclear power plant motors and petrochemical motors, double cooling tubes and double tube sheet heat exchangers are required for protection. normal operation of the motor. In addition, the oil cooler of the power transformer does not allow cooling water to enter the cooling oil, so a large number of double cooling tubes and double tube sheet heat exchangers are used to cool the oil medium.

中文简体

中文简体 English

English Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>